Machining Modeling Intensive - Accelerating On-time delivery and New Product Introduction by Reducing On-Machine Trials

CCAT in partnership with Third Wave Systems will guide engineers, machinists, and programmers to deliver complex, high-value components faster while maintaining stringent quality standards within a model-based engineering (MBE) workflow.

Description

CCAT in partnership with Third Wave Systems will guide engineers, machinists, and programmers to deliver complex, high-value components faster while maintaining stringent quality standards within a model-based engineering (MBE) workflow.

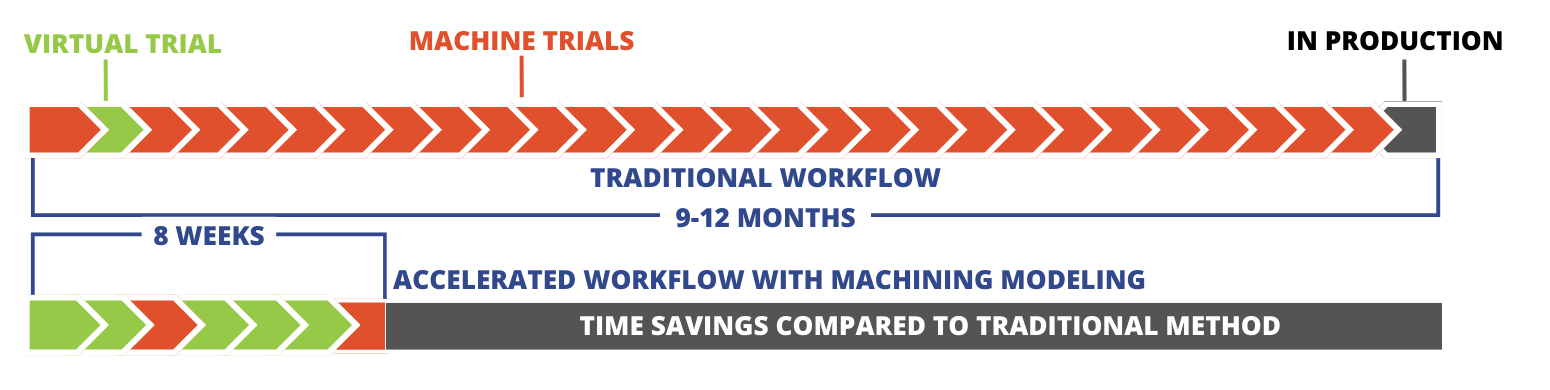

Traditional trial and error machining approaches often lead to delays, scraps, and cost overruns. By understanding heat generation and material stress during the machining process, engineers gain insights that are difficult or impossible to capture through physical machine trials alone. This hands-on workshop will show participants how to evaluate machining strategies, reduce cycle times, and determine toolpaths with confidence before ever cutting a single chip.

Participants will learn how to:

-

Use virtual prototyping to significantly reduce on machine trials

-

Guide toolpath strategies while maintaining part quality by minimizing distortion and deflection

-

Track material stress to improve first pass yield and overall process reliability

Machining Modeling Intensive is a three-day program featuring scenario-based courses that use an industry relevant part, material, and real-world application to demonstrate an end-to-end solution with Third Wave’s machining modeling software.

Day 1

-

Machining Modeling in the Model-based Definition (MBD) Workflow with Third Wave Systems

-

Introduction to the Course Project & Machinability Studies using AdvantEdge

Day 2

-

AdvantEdge Machinability Study Guided Predictive Toolpath Evaluation with Production Module

-

Pick the best strategies with toolpath analysis using Production Module

Day 3

-

Part Quality Analysis for Toolpath Strategy Decisions using Distortio and Production Module

-

Adding Third Wave Machining Modeling Tools to the Digital Thread to Multiply Process Improvements

.jpg)

Target Audience

Machining Modeling Intensive is designed for engineers, machinists, programmers, and manufacturing professionals who want to explore innovative software solutions that can turbocharge machining production, rapid prototyping and continuous improvement.

Learning Objectives

By the end of the course, attendees will be able to apply machining modeling within the digital thread by analyzing and integrating modeling results directly into the toolpath generation process. This approach reduces reliance on physical testing, shortens verification time, lowers costs, and improves part quality and cycle times and enables 5 to 10 times faster time-to-market.