Additive Workflows Essentials

Additive Workflows Training is designed to provide transformative, hands-on, and interactive experiences in AM and 3D printing, supporting your additive technology adoption journey. We’re partnering with local, regional, and national experts, including Adia and SME, to deliver state-of-the-art training at our Additive Manufacturing Lab in East Hartford.

Description

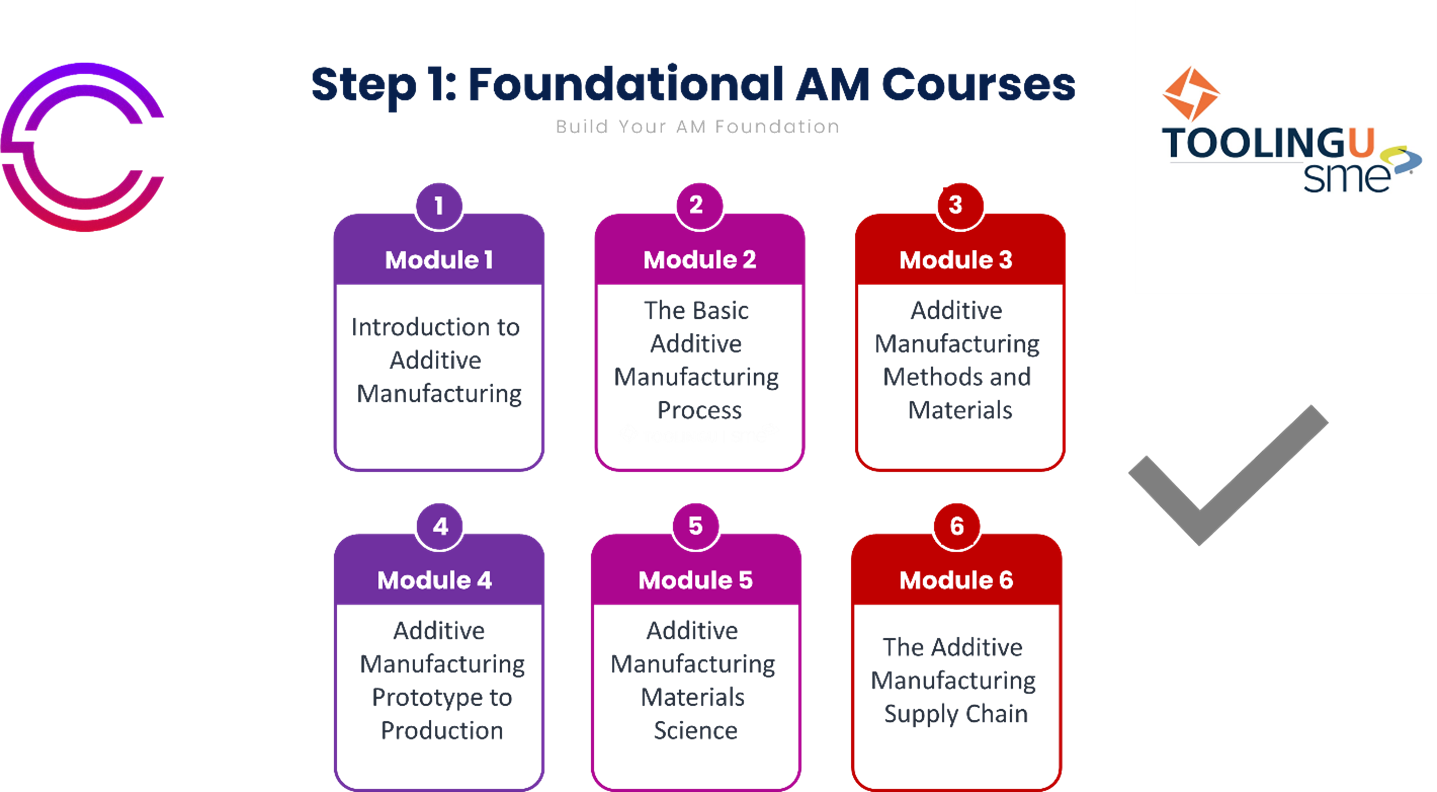

Step 1 - Online Foundational AM Learning with SME-Tooling U

Additive Manufacturing (AM) Foundational courses provide learners with the essential concepts and principles needed to design and produce additive and 3D-printed prototypes, work-in-progress (WIP) tools, and finished parts. The courses, selected from SME-Tooling U, are tailored for beginners and focus on the specific skills and competencies needed to support CCAT’s hands-on training, with an emphasis on AM concepts most critical to the defense industrial supply base. Upon completing this set of online courses, participants will be prepared for in-person, hands-on software and hardware training at our facility in East Hartford, Connecticut. Each module takes 45-60 minutes to complete and must be finished by the first Monday of the month for preceding your 2-Day In-Person Essential Training

Step 2 - In-Person Essentials AM Learning

Essentials courses provide learners with a comprehensive overview of Additive Workflows. Participants will learn advanced technologies for additive part design, DfAM, and topology optimization. In addition, they will explore key AM business cases and learn to evaluate the costs and benefits of additive technology adoption, helping them understand the value proposition for their organization.

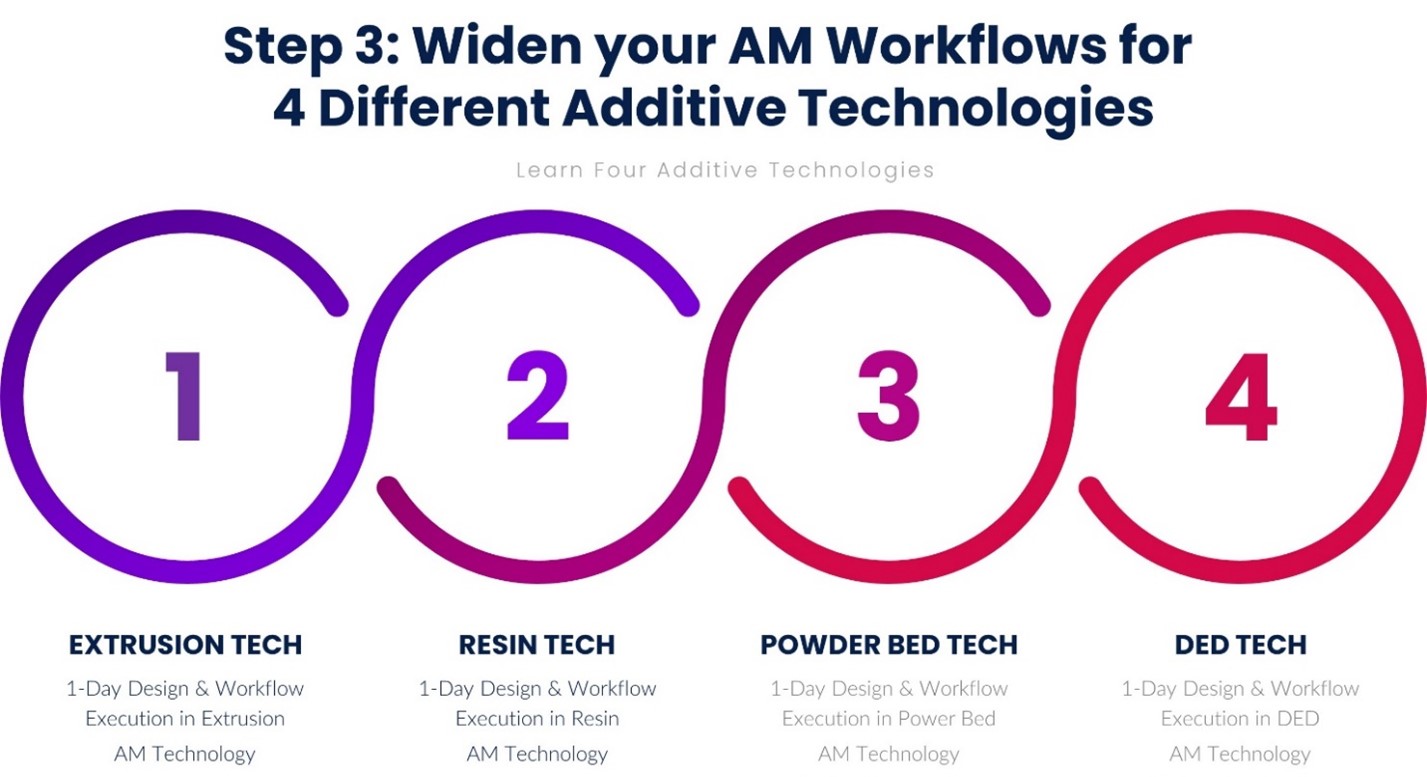

Step 3 - In-Person AM Technology Courses

AM Technology courses offer an in-depth exploration of Additive Workflows for specific technologies. Each AM Technology course is a 1-day, 6-hour session. Technology courses will be offered on Wednesdays, rotating each week, starting with extrusion (second week), resin (third week) and powder bed tech (fourth week). Please note some schedules may vary.

Learning Objectives

- Understand core additive manufacturing (AM) concepts, terminology, materials, and processes relevant to prototyping, tooling, and production.

- Differentiate between major AM technologies, including extrusion, resin, and powder bed systems, and determine the appropriate technology for specific applications.

- Apply principles of Design for Additive Manufacturing (DfAM) and utilize topology optimization tools to enhance part functionality, efficiency, and manufacturability.

- Interpret and evaluate AM workflows from design through post-processing, recognizing the digital thread that connects each phase.

- Demonstrate hands-on proficiency with AM software and hardware to safely set up, operate, and troubleshoot additive systems.

- Analyze print quality, process parameters, and production data to identify variables affecting accuracy, repeatability, and performance.

- Assess the business case and value proposition for AM adoption to support organizational readiness and technology integration within the defense and industrial supply base.

Target Audience

The Additive Workflows Training is designed for anyone interested in learning about additive manufacturing (AM) and how it fits into today’s digital manufacturing environment. Whether you’re a designer, engineer, technician, operator, manager, or simply exploring additive technologies for the first time, this training provides a practical introduction to additive processes and workflows.